Herbert Nadj

Project Management and Product Consulting – Practical and Targeted

Hello, I'm Herbert Nadj. I have been working with engineering products and projects in mechanical and plant engineering for over 30 years. My specialty is printing and coating machines. Particularly in product development projects and in the purchase of decorative printing machines, experience and in-depth knowledge of technology, markets and the latest technologies are crucial.

With my company HN-Engineering, I support companies so that projects can be implemented more smoothly and successfully.

What you can benefit from

- Consultancy and support for small and medium-sized companies in the mechanical and plant engineering sector.

- Experience, knowledge and expertise in markets, manufacturers and technical details.

- Practical solutions for which you make the final decision.

FAQ – Frequently asked questions about my project management services for printing and coating machines

Here you will find a small selection of questions and answers that my clients often ask me. These should give you a first overview of how I work and how I can support you in your next project.

In short, my many years of experience help my clients make better decisions, minimize risks and ensure the long-term success of their projects.

Regarding the search for manufacturers/networks: My many years of experience in the field of decor printing and mechanical engineering enable me to offer a deep insight into the specific requirements and challenges of the industry. As a project manager, I have not only built up extensive technical knowledge but also an extensive network of national and international partners and manufacturers, which gives my clients a clear advantage.

Sustainability: One of the biggest advantages is the ability to find solutions that are both technically and economically optimal. I can help my clients choose the right machine or technology that not only meets their current needs but is also well-equipped to handle future demands.

On the topic of risk minimization: my background knowledge enables me to identify potential risks at an early stage – whether it's selecting machines, integrating new technologies or optimizing existing processes. This proactive approach minimizes unexpected costs and downtime and ensures smooth project execution.

The decor printing industry is facing a number of exciting but challenging developments. One significant trend is the increasing demand for customized, sustainable and environmentally friendly production processes. Consumers and companies are placing more and more value on environmentally conscious solutions, whether it's through the use of resource-saving materials or energy-efficient machines. This development not only requires the use of new technologies, but also close cooperation with manufacturers and suppliers to find solutions that meet both ecological and production requirements.

Another trend is digital transformation. Digitization is increasingly affecting all areas of production, from machine control to process optimization. Companies need to digitally network their production processes to increase efficiency and secure competitive advantage. The integration of IoT (Internet of Things), automation and big data in decor printing machines is an increasing focus here.

Seamlessly integrate technologies into existing production lines. Companies are often faced with the task of combining their machinery with new digital solutions without disrupting ongoing production processes. In-depth knowledge of both the technology and the operational processes is crucial here.

To deal with these trends and challenges, I apply my experience in mechanical engineering and project management to provide companies in the decor printing industry with practical and future-proof solutions. I support my clients in selecting and integrating new technologies, advise them on choosing sustainable machines and help them take their production processes to the next level. By taking a customized approach and working closely with them, I ensure that my clients not only keep up with current trends but are also able to achieve long-term success.

Hurdle no. 1 in my view: When it comes to purchasing decor printing machines, there are several hurdles that companies often overlook. One of the biggest is insufficient planning for long-term production requirements. Many companies initially focus only on the purchase price and the performance of the machines, without considering long-term profitability and flexibility. However, the scalability of the machine, its maintenance requirements and the possibility of integrating new technologies play a crucial role.

Hurdle no. 2 in my view: Another hurdle is selecting the right manufacturer. A provider's quality and service often vary greatly, and it is important to choose a partner that not only delivers a reliable machine but also offers excellent customer support and a good service offering.

Hurdle no. 3 in my view: In addition, there are technical challenges, such as integrating new machines into existing production processes. Without a thorough analysis of compatibility and necessary adjustments, this can lead to unexpected downtime and inefficient processes.

I help my clients avoid these pitfalls by conducting a thorough needs analysis, comparing possible manufacturers and machines, and supporting them in integrating and optimizing the new machines. This way, we ensure that your decor printing machine not only meets your current requirements but is also future-proof and economical.

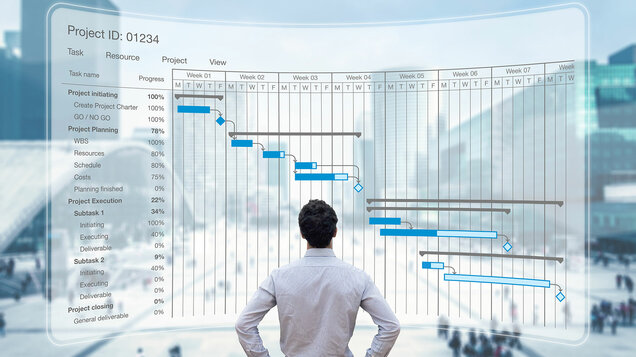

1 - Planning and control: Thorough planning and continuous control are essential to complete projects on time and within budget. At the beginning of each project, I make sure that all requirements and objectives are clearly defined. This includes working with my clients to precisely define the project scope, technical requirements, and time and budget constraints.

2 - Budget and schedule coordination: During project implementation, I make sure that milestones are regularly reviewed and progress is monitored. This enables me to identify deviations from the schedule or budget at an early stage and take appropriate action immediately. Close collaboration with all partners, suppliers and manufacturers involved ensures that everyone is always up to date and that possible delays or additional costs are identified at an early stage.

3. Transparency: I regularly keep my clients informed about the project status and discuss possible adjustments together when unexpected challenges arise. This proactive approach ensures that problems can be quickly resolved or avoided altogether.